Zero Liquid Discharge ZLD

Zero Liquid Discharge

Caring for the future

Water is one of the most valuable resources on Earth. Global environmental awareness, the desire for sustainability, and the focus on conserving and protecting our water supplies are steadily resulting in more environmental regulations and stricter rules regarding the use and disposal of water in industry. The machine solutions developed by SIEBTECHNIK TEMA for Zero Liquid Discharge (ZLD) projects are used in many industrial sectors to purify or recycle process water and to recover valuable substances from wastewater.

The Earth’s resources are finite. For decades, knowledge of this scarcity of resources and raw materials has led to the sustainable recovery of recyclable materials, which are then returned to the value chain.

Water is particularly significant here.

Only 2.5% of the water on Earth is fresh water. Only a small part is really accessible to humanity, namely 0.3% (in lakes, rivers and reservoirs).

Sustainable resource saving

But demand for high-quality water is increasing, driven by ecological changes, environmental factors, the growing world population, and increasing urbanization.

This fact has led to greater environmental awareness worldwide regarding the availability and quality of water. As a result, there are increasingly stringent government regulations regarding the disposal of industrial wastewater.

Due to scarce water resources, and rising costs for water treatment and wastewater disposal, the use and conservation of water is a key issue in the manufacturing industry around the world. The focus here is often on repeatedly using treated water and reducing wastewater volumes, and even on avoiding wastewater entirely. Demand for new and increasingly efficient recycling technologies is growing, especially in regions that have limited access to available water sources and wastewater disposal options.

Centrifuges for ZLD

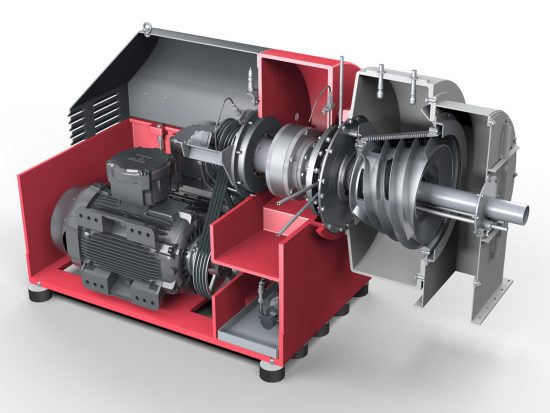

Solid-liquid separation is the critical final step in most ZLD processes, as this is where the remaining water is separated from the solids, in most cases salts.

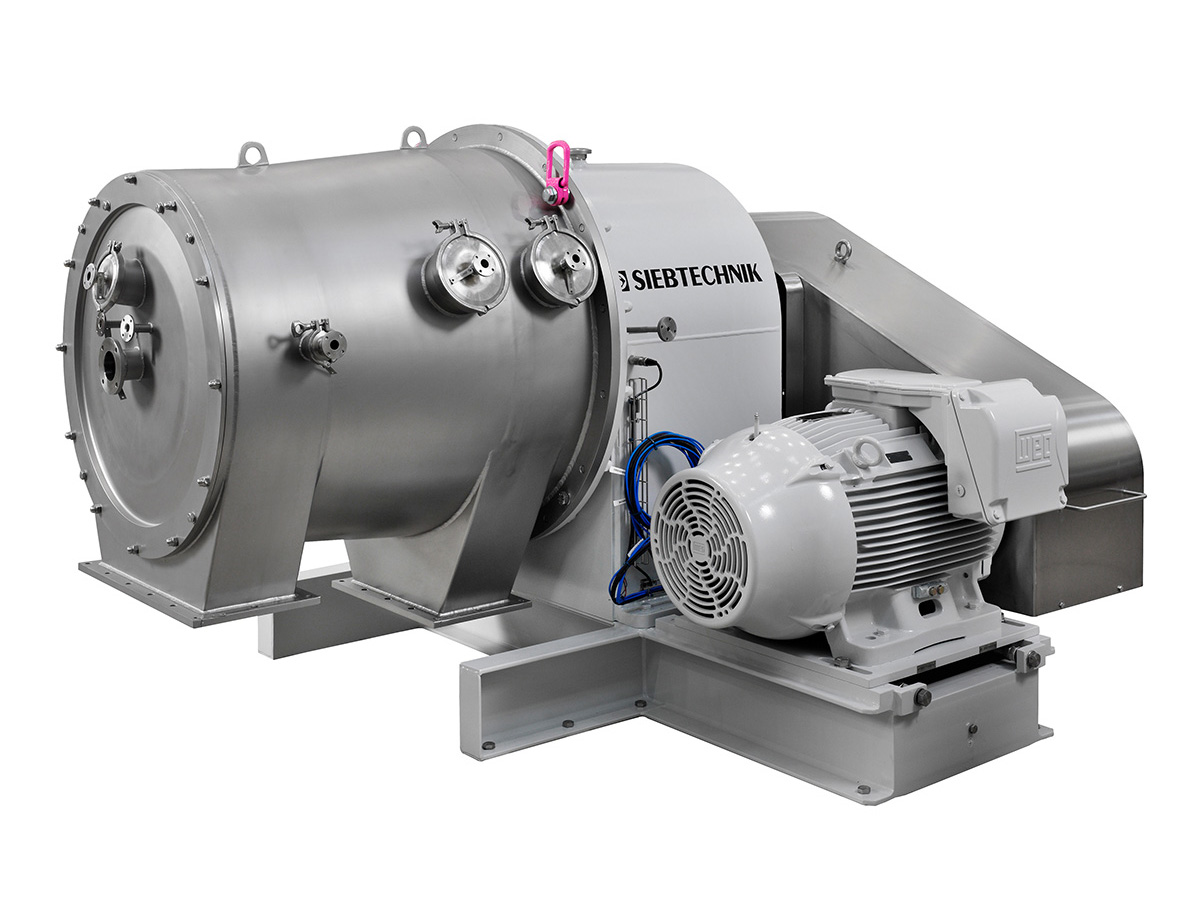

Dewatering is mostly done with decanters, SHORTBOWL decanters, pusher centrifuges and CONTURBEX centrifuges. For dewatering coarse residue, our HSG vibrating centrifuges have proven effective.

Finer mixed salts from crystallization plants are centrifuged using downstream SHORTBOWL decanters, pusher centrifuges and CONTURBEX centrifuges at temperatures sometimes exceeding 100°C.

The high-alloy stainless steels, Hastelloy® and titanium materials required for these machines are provided with appropriate wear protection made of tungsten carbide, Stellite® or ceramic tiles.

In this innovation-driven market, we are also constantly developing new and more efficient coating, bonding and joining technology solutions for our customers.

Each ZLD process and each customer has their own specific requirements. SIEBTECHNIK TEMA has an extensive portfolio of centrifuges and dryers that can be tailored to your exact requirements. Our experts will be happy to advise you!

The Benefits of Zero Liquid Discharge

ZLD improves the environmental and economic footprint of a plant

In order to increase the environmental friendliness of industrial plants, ZLD is used in a wide variety of fields. Zero Liquid Discharge improves the environmental and economic footprint of a plant. Firstly by reusing water, and secondly by avoiding the discharge of wastewater, which could incur high costs or damage the environment. In this way, ZLD helps companies comply with strict regulations and guidelines regarding wastewater disposal and water reuse, as well as protecting the local environment. In addition, ZLD enables the recovery of valuable resources from wastewater, which can be reused in the industrial process or sold.

Zero Liquid Discharge helps to:

- Protect the environment and water resources

- Fulfill government regulations

- Achieve higher levels of water recovery

- Reduce wastewater volumes

- Reduce costs

- Recover salts from wastewater (e.g. potassium sulfate, sodium sulfate, sodium chloride, lithium salts, mixed salts)

Industries that use ZLD include e.g.:

- Pharmaceuticals

- Chemicals

- Oil, gas & refineries

- Power generation

- Steel & mining

- Cellulose & paper

- Tanning & textile dyeing

- Beverages & food

- Drinking water treatment

- Agriculture

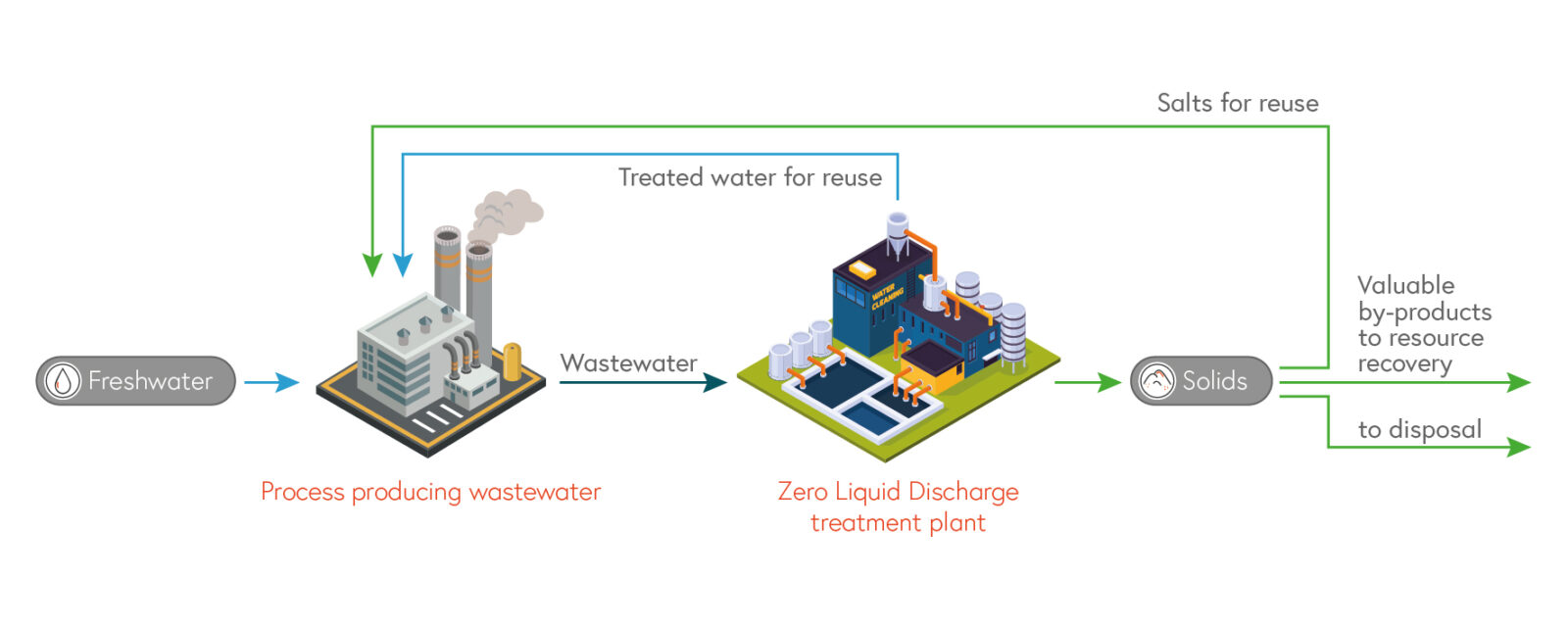

What is ZLD?

Zero Liquid Discharge (ZLD) is a treatment process focused on the economical reduction of wastewater. This produces clean water suitable for reuse, saving money and protecting the environment.

ZLD systems utilize advanced wastewater/desalination technologies to treat and recycle virtually all the wastewater generated. In this process, the components dissolved in the water are converted into reusable solids such as sludge and salt.

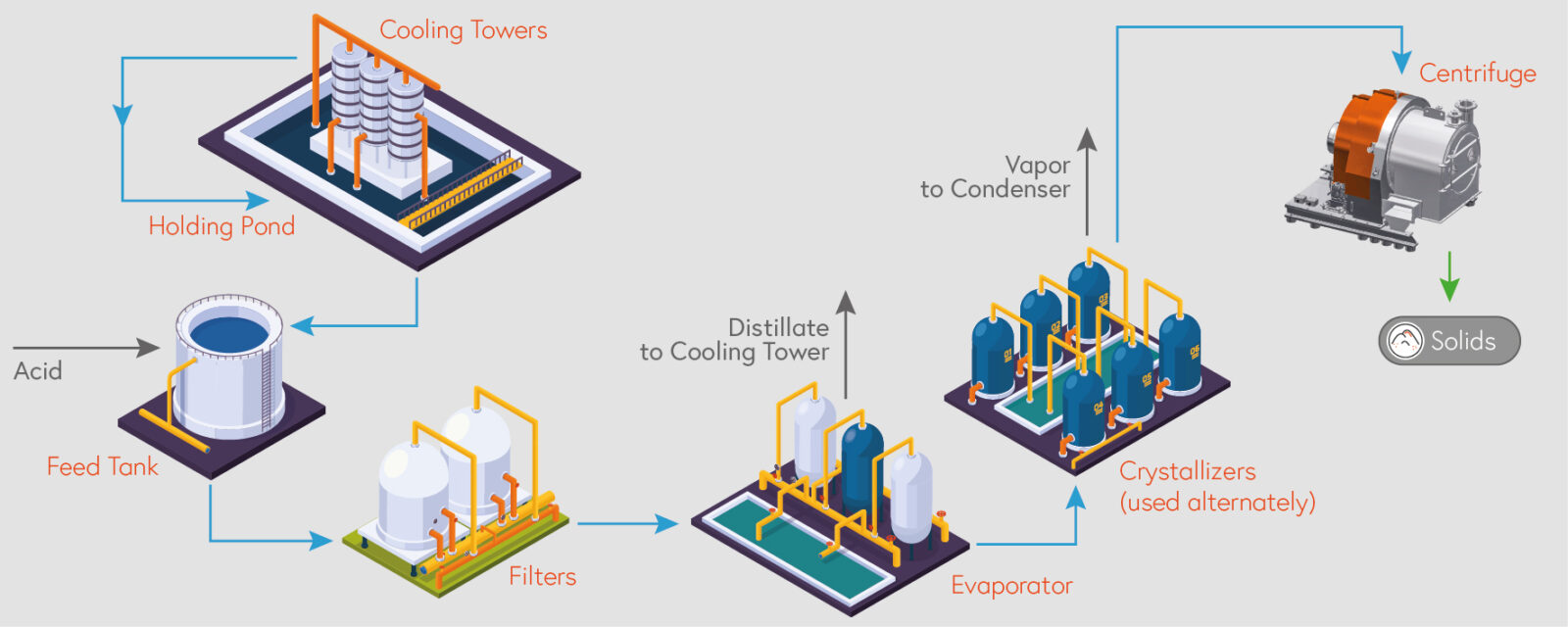

Different technologies are typically combined, such as thermal evaporation, crystallization, desalination and drying, and centrifugal separation.

The ZLD process

The first step is to filter or precipitate waste and chemicals that are easy to remove. The wastewater is then concentrated by means of evaporation. In the third step, the concentrated waste stream is fed into a crystallizer. In the last and decisive step, this suspension of water and crystallized solid is separated using a centrifuge. The efficiency of the upstream steps matters little; it is the use of the right centrifuge that determines the overall efficiency of the plant.

ZLD Process

If you are interested in what one of our experts has to say about ZLD, read this article.

Get even more information about Zero Liquid Discharge and why the CONTURBEX offfers a number of advantages in ZLD processes.

Conturbex centrifuges ideal for zero liquid discharge process

Downloads

Zero Liquid DischargeCentrifuges

CONTURBEX screen scroll centrifuge

SIEBTECHNIK TEMA - One Solution. Worldwide.