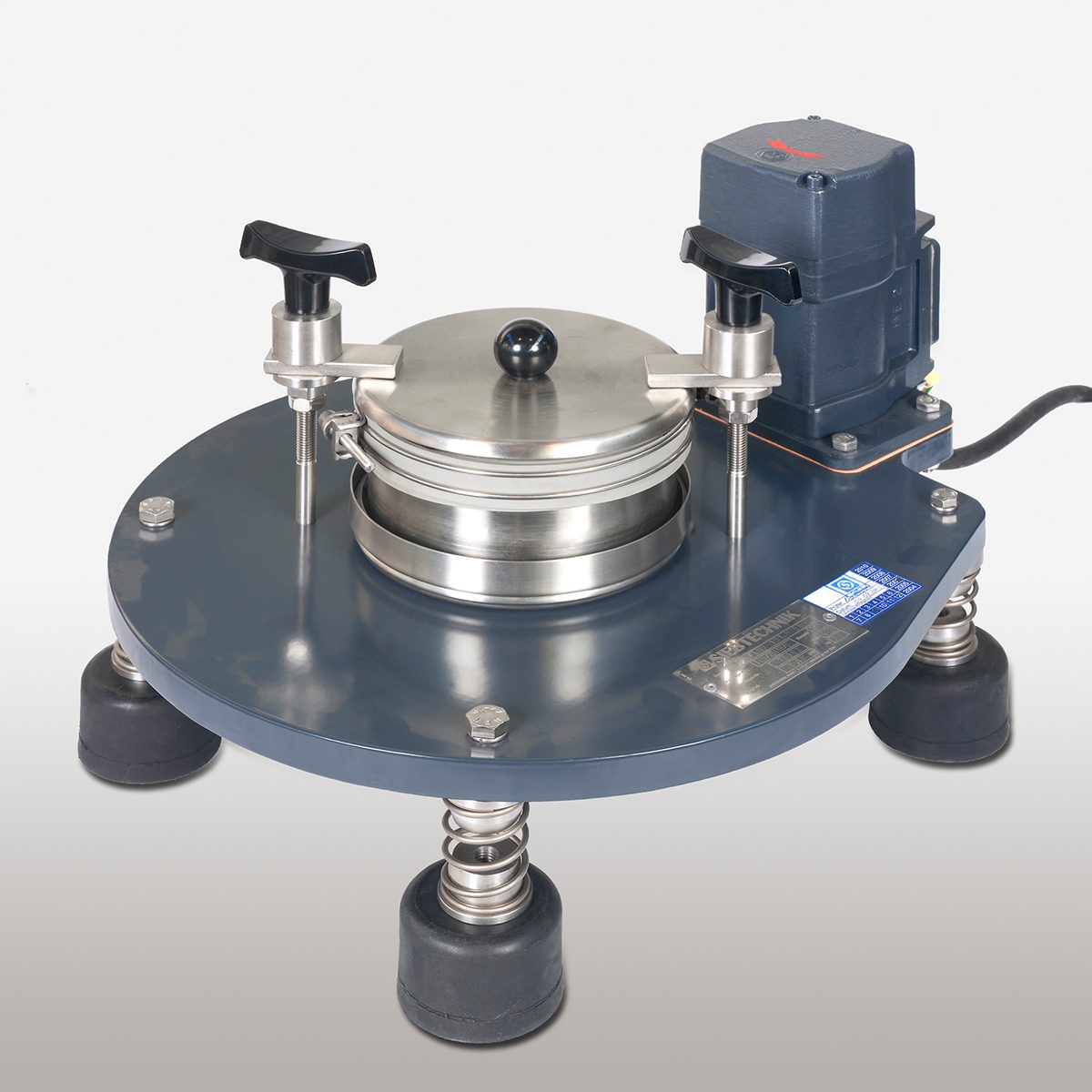

Control screening machine PERFLUX

Control screening machine PERFLUX

Impurities contained in powders and suspensions (for example screws, scraps of paper or cleaning rags), can, if they remain undetected, lead to expensive repairs of machines and equipment or may even cause shut-down of production.

Therefore you should protect your sensitive production processes with the control screening machines of our new PERFLUX-generation, which reliably remove impurities and agglomerates from powders and suspensions.

The main scope of application for these machines is the control screening of materials before they are packed, shipped or processed for various industries, such as the building material industry, paint industry, chemical industry, food industry and pharmaceutical industry. These machines are also ideally suited as screening machines for small manufacturing processes.

Operating Behavior & Mechanical Characteristics

Our new PERFLUX-generation consists of a highly stiffened aluminium frame, which is put into gyratory motions by the attached unbalance motor.

This gyratory motion allows a higly efficient and effective screening process with only one motor, thereby keeping operating cost low. Due to its compact dimensions, the machine can easily be integrated into any production process.

Accessory

Depending on its field of application, the PERFLUX can be supplied with

- sifting disc of stainless steel, with or without reject discharge, for dry screening

- sifting disc of stainless steel without reject discharge, for wet screening

- cover and funnel of stainless steel to ensure dust-free processing

- execution for operation in ex-areas according ATEX 100 a

- brush device for screening of difficult material and for the crushing of agglomerates

- various base frames

Technical specification

| PERFLUX | 151 | 301 | 501 | 801 | |

|---|---|---|---|---|---|

| Screen sureface diameter | mm | 150 | 300 | 500 | 800 |

| Mesh opening | µm | > 40 | > 40 | > 63 | > 63 |

| Motor | kW | 0.16 | 0.16 | 0.16 | 0.50 |

| Weight incl.mesh, cover and funnel | kg | approx. 18 | approx. 20 | approx. 25 | approx. 60 |

| Dimensions | A | 490 | 490 | 690 | 1182 |

| B | 400 | 400 | 600 | 948 | |

| C | 261 | 302 | 335 | 410 | |

| D | 235 | 285 | 330 | 420 | |

| E | 10 | 50 | 82 | 114 | |

| F | 250 | 252 | 252 | 296 | |

| G | 100 | 85 | 100 | 131 | |

| H | 50 | 100 | 200 | 200 | |

| I | 50 | 100 | 200 | 200 | |

| Dimensions without obligations | |||||

Application

Advantages

- low-wear and low-maintenance design

- compact dimensions

- can be optimally integrated in existing production processes