Semi-mobile pulsator jig

Semi-mobile pulsator jig

Density sorting: a complete system

Fast & simple to install – ideal for flexible operation worldwide!

Our semi-mobile pulsator jig is the perfect solution whenever you want to avoid long transport routes, or where the fact that the material is produced for a limited period of time only makes the construction of a plant uneconomical.

Especially in the recycling industry, the deployment locations are usually only temporary. Our semi-mobile pulsator jig has been developed especially for such applications.

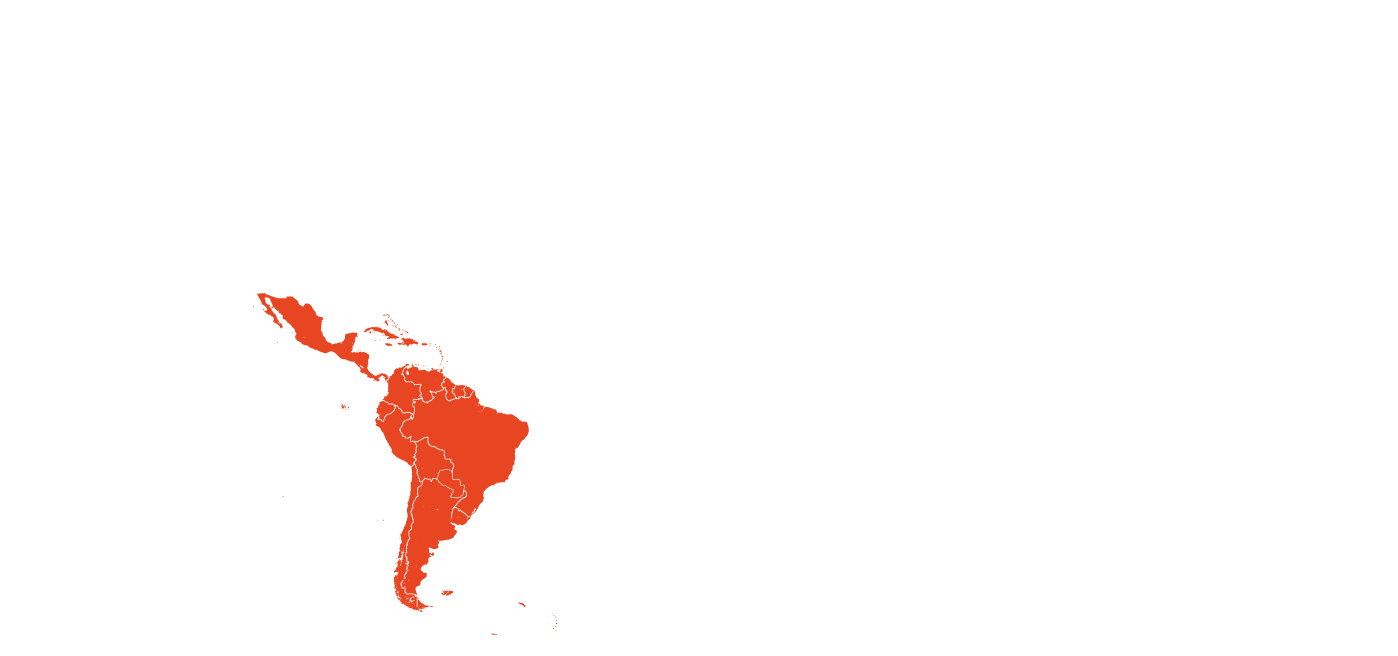

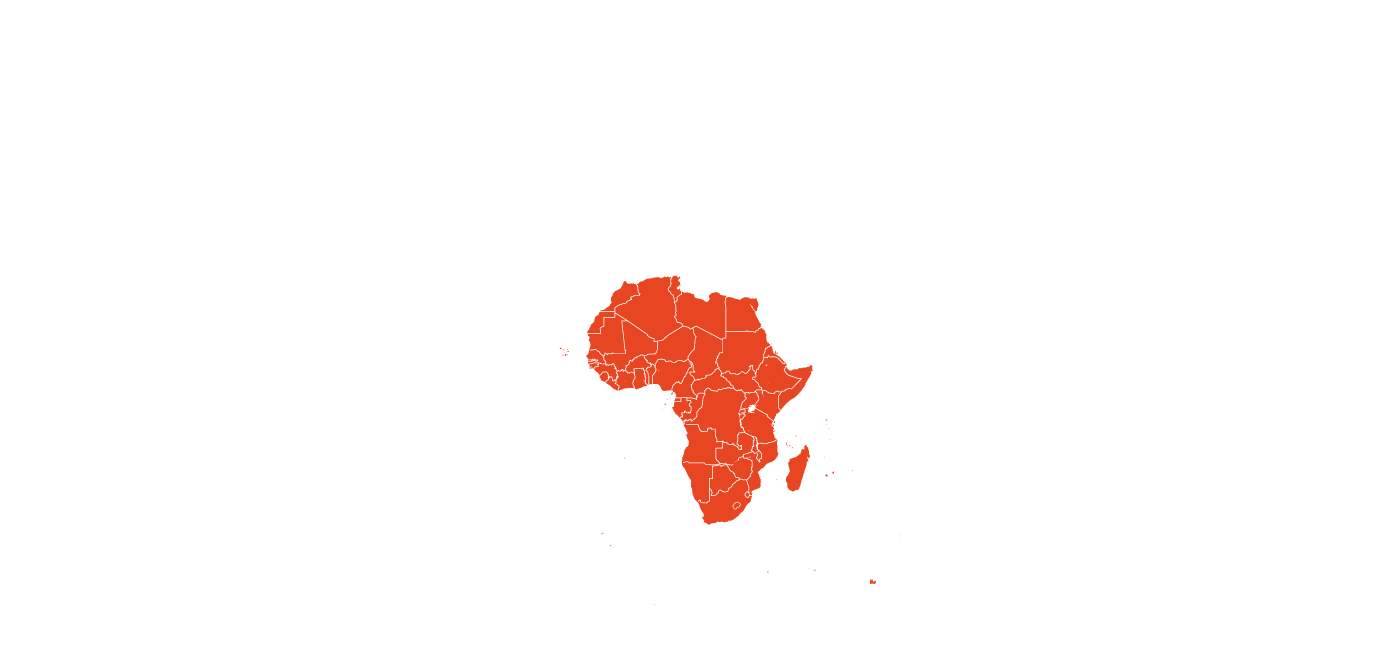

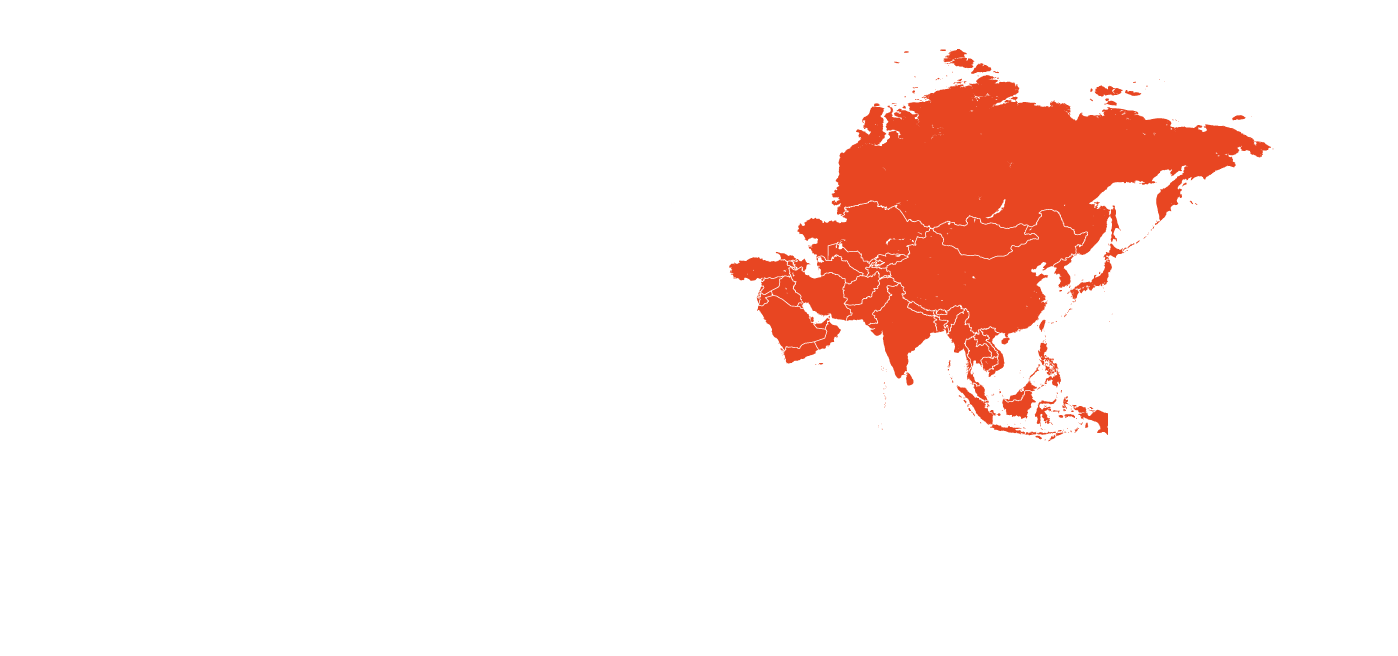

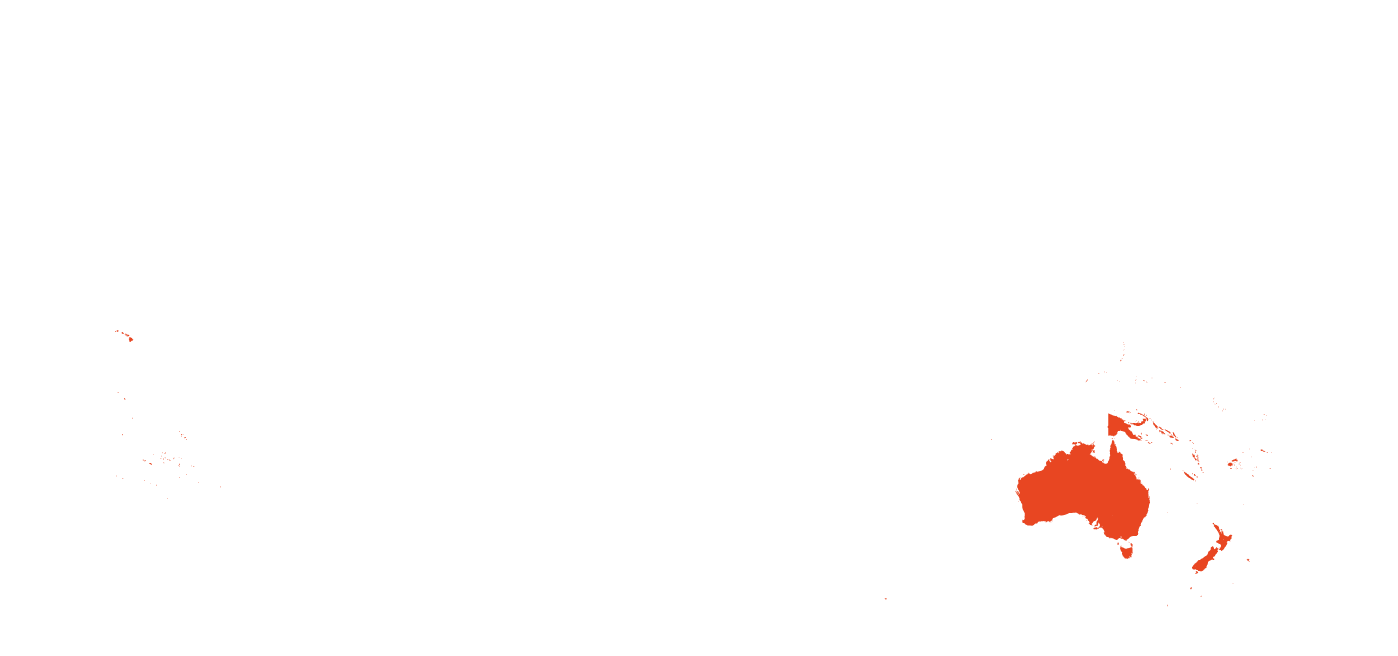

Perform density sorting directly where material is produced, for example, e.g.:

- Demolition work & construction waste sorting

- Soil decontamination work

- Waste heap sorting

- Gravel & ballast sorting

- and many more

Our semi-mobile pulsator jig helps you increase the quantity and quality of recycled material, as well as reducing transport distances and waste. This allows you to save resources and reduce costs.

It is also a welcome supplement to semi-mobile crushing and sorting systems.

Find out for yourself! We will be happy to advise you!

Application examples

Construction waste recycling

Demolition work produces various recyclable materials. Brick, lightweight concrete, plastic, wood and glass are all materials that should be recycled in the interests of sustainability and the material cycle.

Beyond the reuse of plastic, wood and glass, the separation of lightweight materials from the residual waste makes it possible, e.g., to make recycled concrete useful after appropriate processing.

Semi-mobile solutions such as our type SKC pulsator jig are perfectly suited for such work. They can be set up near the demolition site for a limited time, helping to increase recycling rates, improve the quality of the material, and reduce the amount of residual waste that needs to be transported to a landfill for disposal.

Soil decontamination

Our soil performs various tasks. It forms the nutritional basis and habitat for humans, animals & plants. It contains & protects drinking water, is a source of raw materials, and forms the ground we build on.

Since new soil is only formed over geological time periods, and is therefore a non-renewable resource, decontamination is particularly important.

Density sorting can be used during soil decontamination to remove waste materials such as branches, stones, glass and plastic from the excavated material. This eventually produces new fertile soil.

Waste heap sorting

Old waste heaps of all kinds frequently still contain reserves of raw materials, which can be accessed through renewed sorting.

In view of dwindling raw material reserves and for reasons of sustainability, this topic is growing in importance.

(Gravel) excavation sites with only low volumes

When excavation sites promise only a small amount of raw material, semi-mobile machines are the optimal solution, because building a new plant is uneconomical. Transport to and further processing at existing plants consumes resources unnecessarily, however, and is also cost-intensive.

The type SKC pulsator jig can be used directly at the excavation site and – after the deposit is exhausted – transported to the next operation site.

Density sorting: a complete system. Fast & simple to install – ideal for flexible operation. Worldwide. Find out for yourself!

Application

- Demolition waste

- Gravel

- Crushed rock

- Shredder material

- Waste

- Incineration slag

- Waste slag

- Litter

- Basalt

- Black coal

- Blast furnace slag

- Chalk sand

- Limestone sand

- Coal

- Coal middlings

- Coal from coal washery

- Concrete sand

- Dolomite

- Fine coal

- Granite

- Greywacke

- Hard rock – hard stone

- Iron ore sand

- Minerals

- Ore

- Pea gravel

- Grain of maize

- Pellets (Polymer)

- Pellets (Sinter)

- Sand

- Pumice sand

- Sand from canalization

- Shell sand

- Silica sand

- Tantalum

Components:

- Pulsator jig for density sorting

- Dewatering channel for dewatering light & heavy material

- Cyclone for desludging the circulating water

- 2 pumps for the water circuit

- Collecting tank with level monitoring

- Overall control system with separate control panel