Slotted-vessel samplers

Slotted-vessel samplers

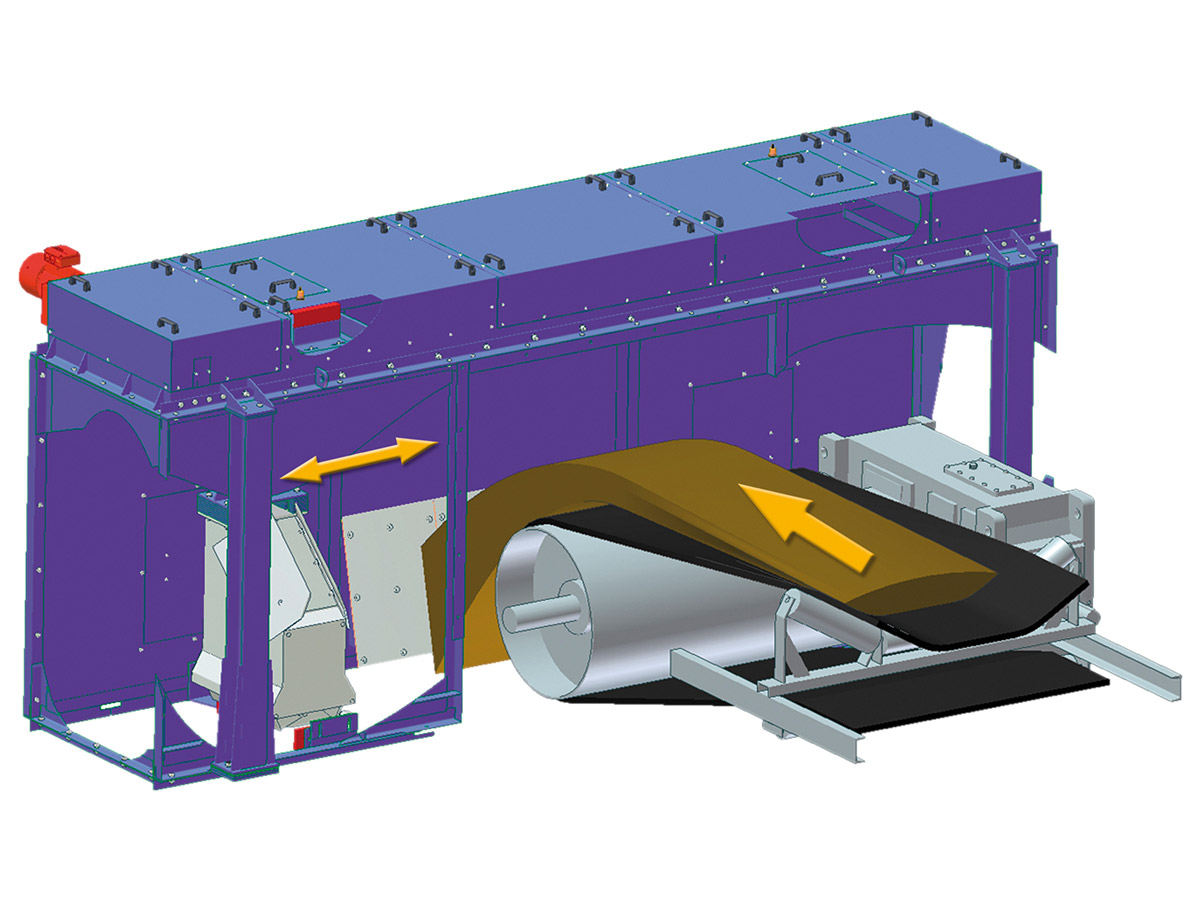

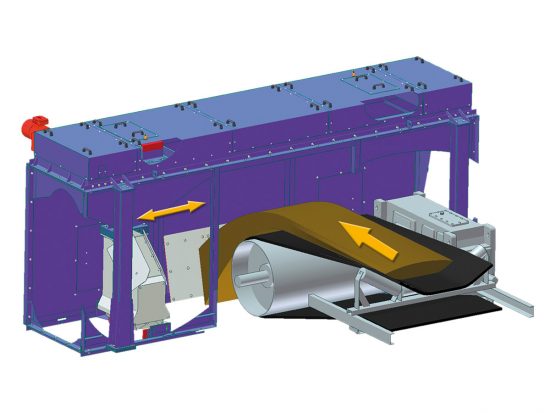

The slotted-vessel sampler is implemented for sampling materials at the belt head or in the downpipe. This sampling principle is based on a slotted-vessel with defined intake slot vertical to the dropping material stream that records the material stream’s entire thickness at a constant speed.

The slotted-vessel sampler runs through the material stream from the waiting position with the base flap usually opened, closing this flap when the reverse position is reached.

The sampler now runs through the product stream with the base flap closed again at constant speed and thus takes a representative sample.

On the usually conical vessel reaching its waiting position, the base flap is opened by means of stops and a sophisticated lever system, and the slotted-vessel emptied.

The sampler’s waiting position is invariably located outside the material stream, thus minimizing wear to the sampler.

Advantages

- Simple and low-maintenance design

- High tolerance of unwanted materials in the product stream

- Application-specific drives for the slotted-vessel carriage using steel chains, rubber-block chains or toothed belts

- Travel drives to be arranged individually to suit local conditions

- Complete integration of the sampler into belt transfer stations

- Variable travel speed of the sampler by means of frequency inverter

- Large slotted-vessel volume up to 1000 dm³