Machine service

OEM service

Your basis for high availability and reliable production

SIEBTECHNIK offers you as an OEM supplier the service that ensures your production. Our services provide you with the necessary spare parts and personal service, develop with you an individual maintenance and service concept and so guarantee you the highest possible machine availability.

The SIEBTECHNIK service combines four essential modules for this:

- Availability of spare parts

- Maintenance, retrofit & repair

- Remote service & diagnosis

- Preventive maintenance

Work with us to prepare your machine service package!

Availability of spare parts

With SIEBTECHNIK you have the OEM by your side. SIEBTECHNIK stocks standard spare parts, especially components for the drive/bearing system. Our staff would be pleased to analyse your stocks on site and – depending on machine loads and production conditions – prepare an individual spare parts package to minimise machine down-times. Complete service and repair kits additionally systematise and simplify maintenance.

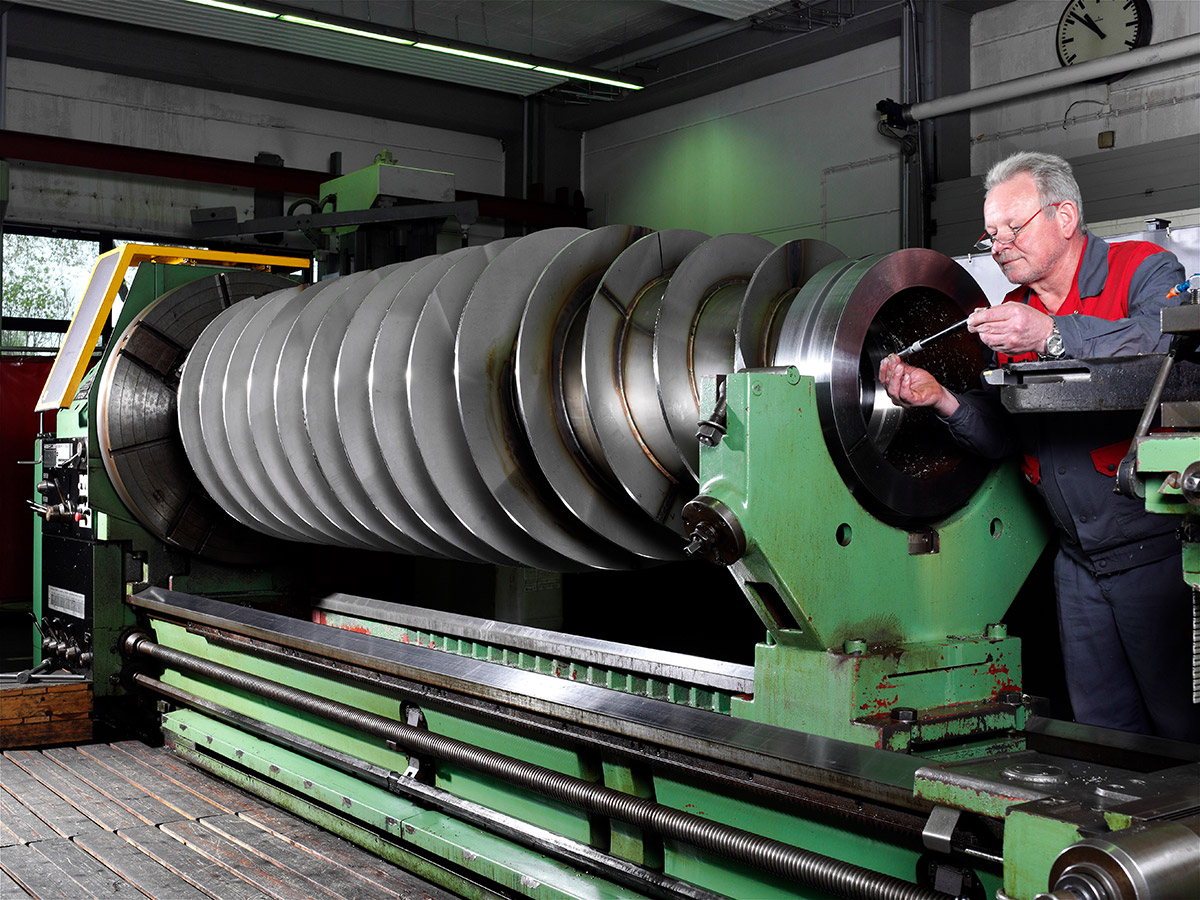

Maintenance, retrofit & repair

SIEBTECHNIK TEMA specialists use their experience worldwide to support you with service and maintenance work. Contact persons are available all over the world and will coordinate service assignments at your works at short notice. Please get in contact.

As part of centrifuge maintenance, machines can be modernized. Retrofit measures are often essential for you as the operator in order to comply with updated operating regulations, e.g. according to ATEX or hygiene.

Also in case of repair SIEBTECHNIK TEMA is your service partner for a quick restoration of production operation. The joint analysis of the cause of damage is an important building block for further damage prevention, i.e. preventive maintenance. Often there is the possibility of a replacement machine to bridge the unplanned downtime.

Remote Service & Diagnosis

The analysis of machine operation is made simple and fast by a remote maintenance module. Thus, operating parameters can be analyzed online by our specialists and the current machine condition can be evaluated. With a centrifuge control system from SIEBTECHNIK TEMA, this is not just an option, but standard. But also for an installed third-party control system, for example with the help of a data collector, online support could be implemented with little effort. We would be pleased to check the possibilities.

Your centrifuge is not yet sufficiently instrumented? SIEBTECHNIK TEMA offers extensive sensor technology, e.g. for monitoring machine speed, vibration and temperature, bearing condition and the lubricating oil circuit. Special equipment also enables continuous monitoring of lubricating oil quality. Contact us.

Fast communication and competent assistance are essential, not only in the event of an unplanned shutdown, but also in the case of conspicuous machine operation. In these cases SIEBTECHNIK TEMA offers the following options:

- Telephone or video conference with our centrifuge specialists

- Analysis of operating data, photo and video material

- Mobile analysis kit for on-site measurement of centrifuge operation (stroboscope, vibration meter, IR thermometer)

- Industrial data goggles for “hands-free” communication

Preventive maintenance

“Preventive maintenance” is the most important instrument for early damage detection, i.e. for avoiding unplanned downtimes – in short: for avoiding additional costs and production loss. Here SIEBTECHNIK TEMA offers you the following modules:

- Mobile, recurring machine measurement on site

- Vibration frequency analysis

- Sensor check for vibration shakers

- Oil pressure history

- Oil condition check

- Technical consulting/ machine audit

- Machine history analysis

- Stock analysis

- Information on retrofits and upgrades

- Trainings/ Workshops